UK MACHINE VISION &

AUTOMATION COMPANY

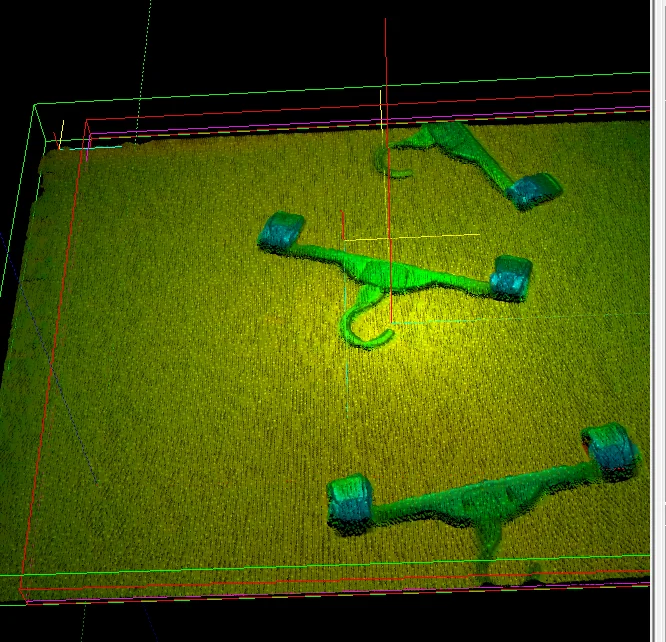

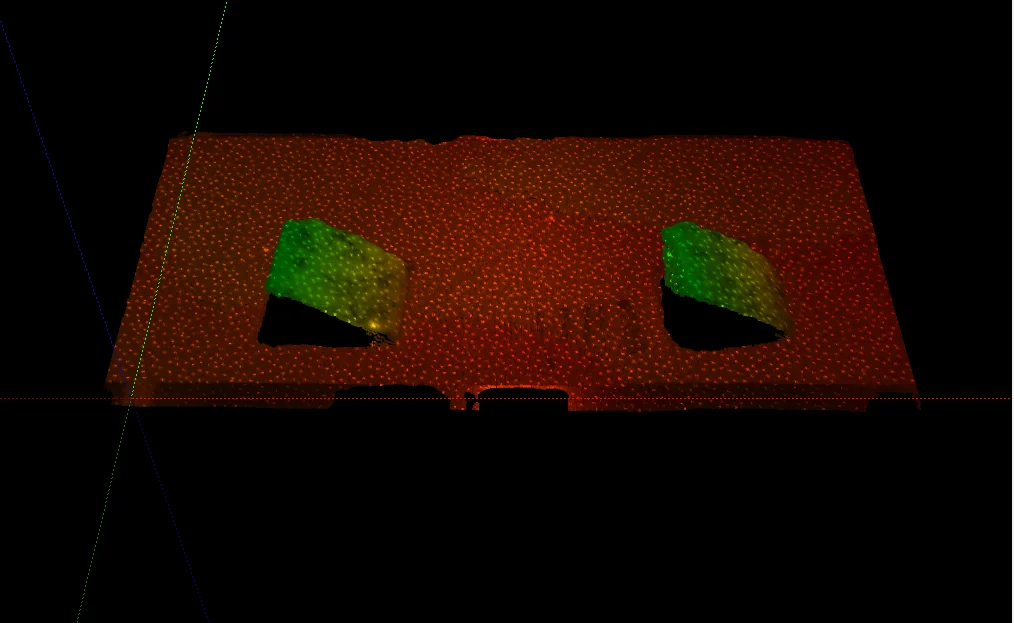

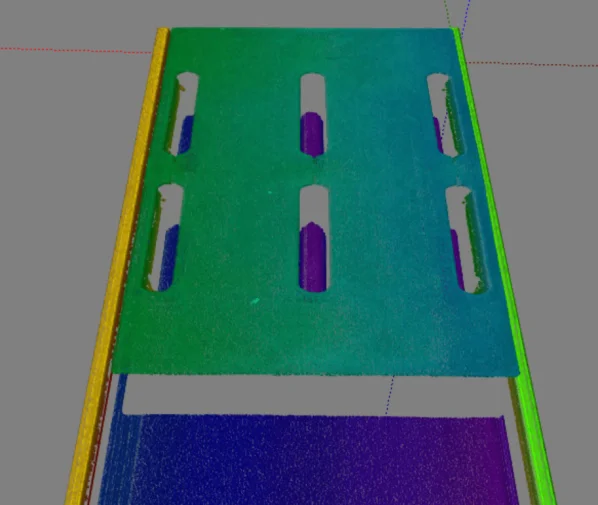

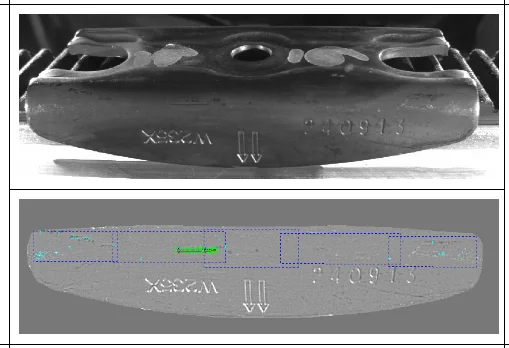

REDUCING THE RISK AND IMPROVING PRODUCTIVITY

The first Scorpion Vision Software based automation system was conceived over 25 years ago. So, with a long track record of delivering reliable automation systems in a very broad range of vertical sectors, you can be sure that Scorpion Vision Ltd will be a good partner for your machine vision system requirements.

Whether you are a manufacturer of a high volume product, looking to reduce labour costs and improve margin; or a machine builder/integrator who wants to safely outsource their machine vision requirements to a highly experienced and professional team, you should talk to us.

PROJECTS

- All Industries

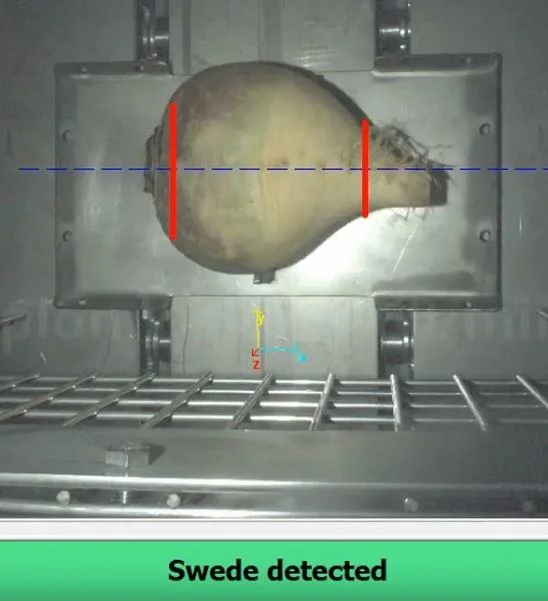

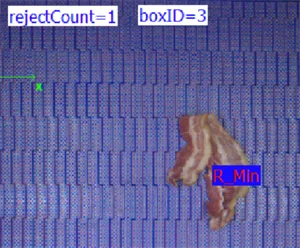

- Food

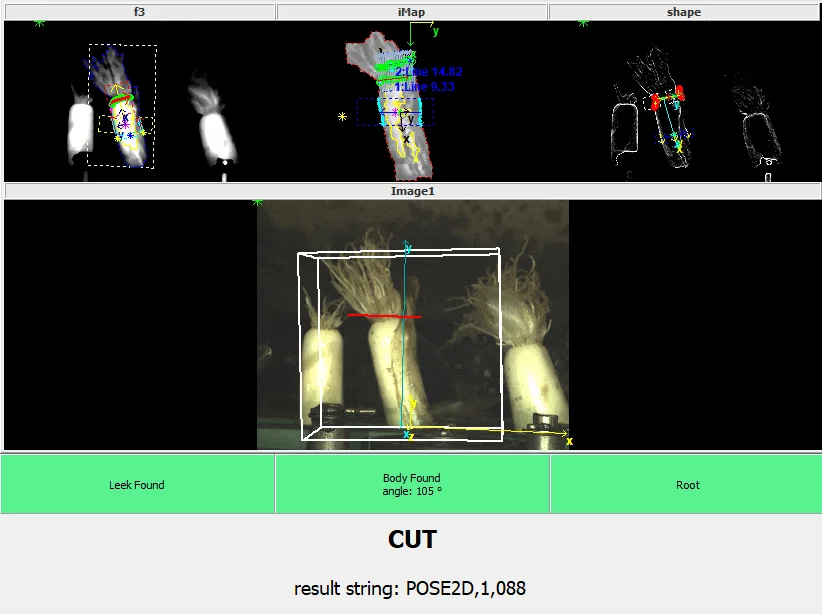

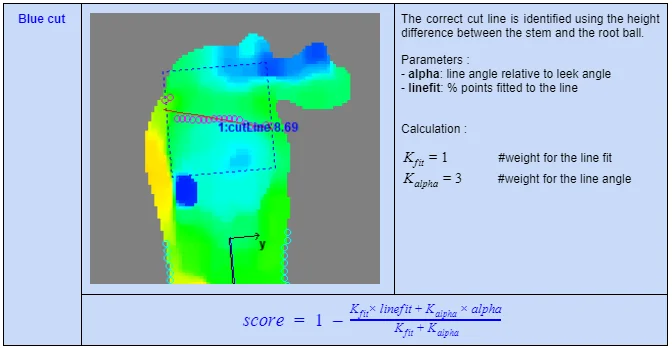

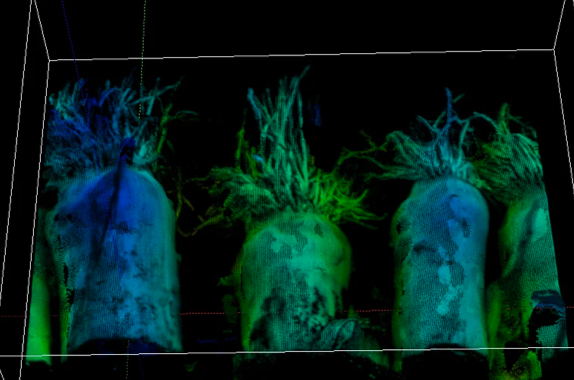

- Horticulture

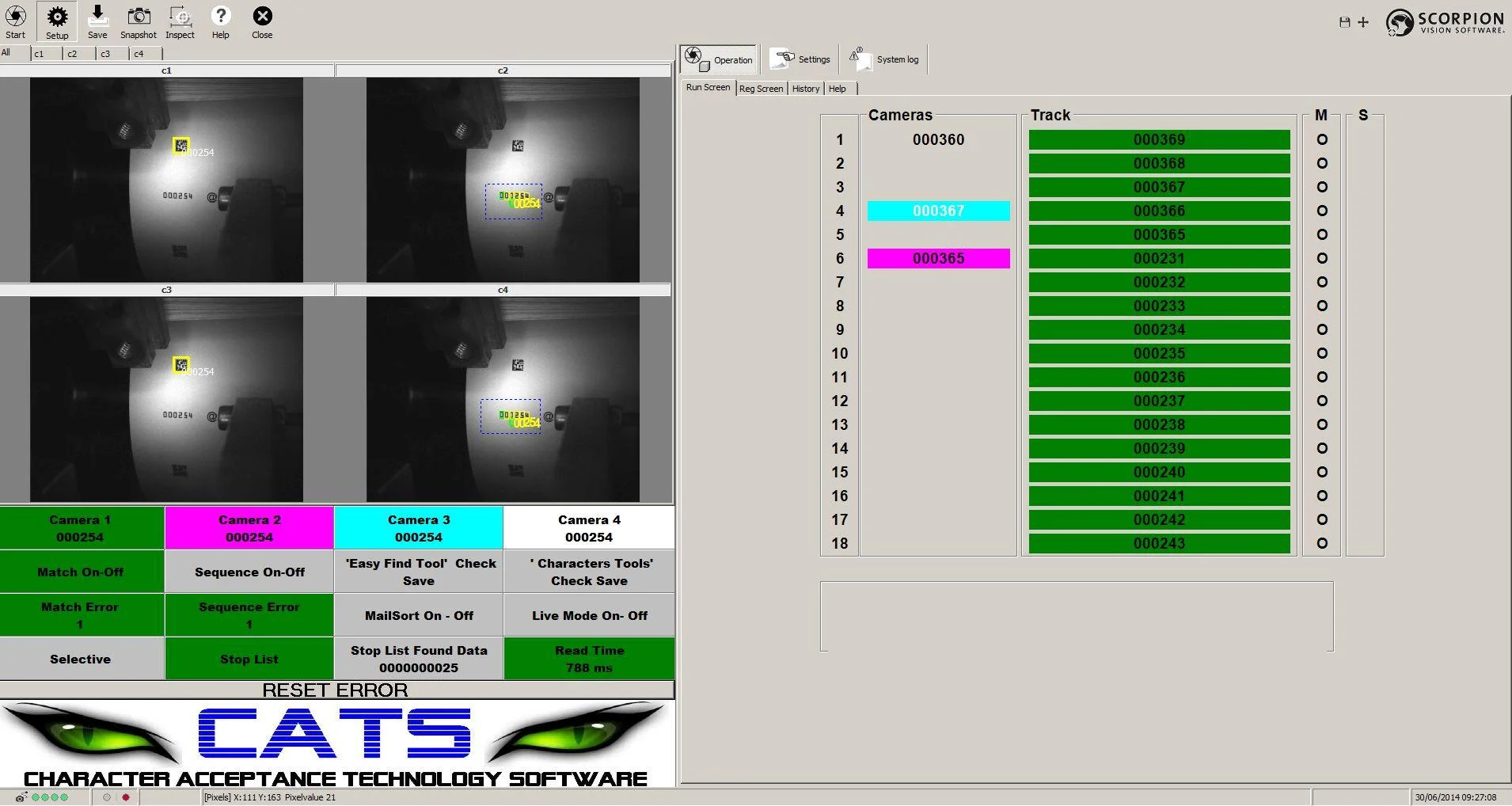

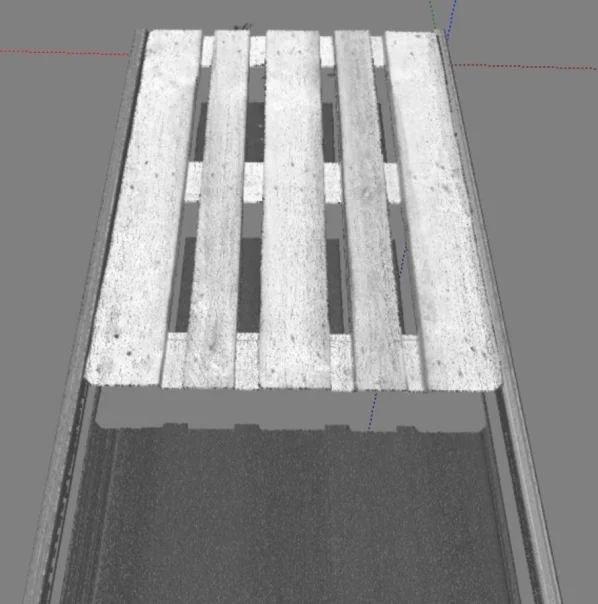

- Logistics

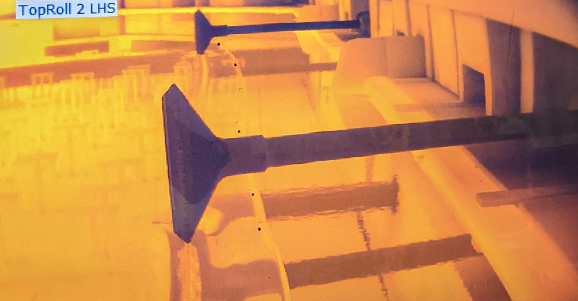

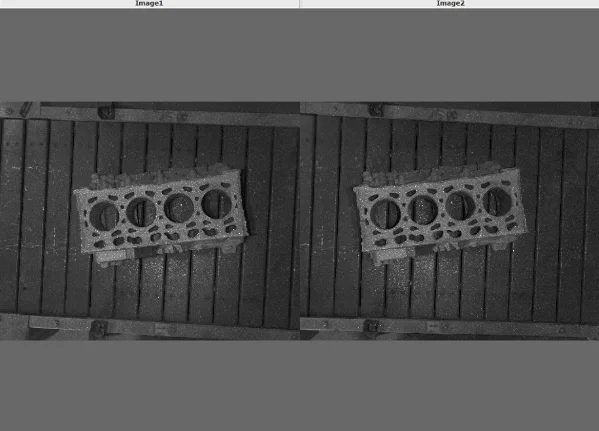

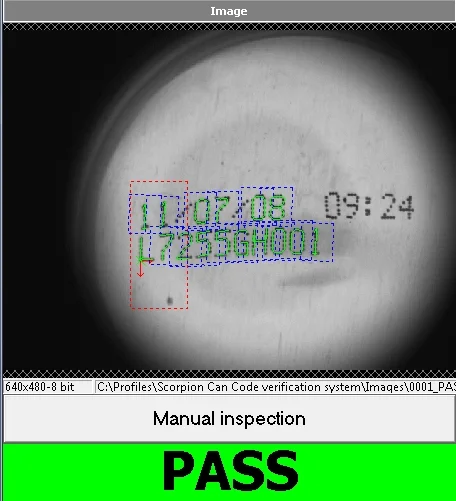

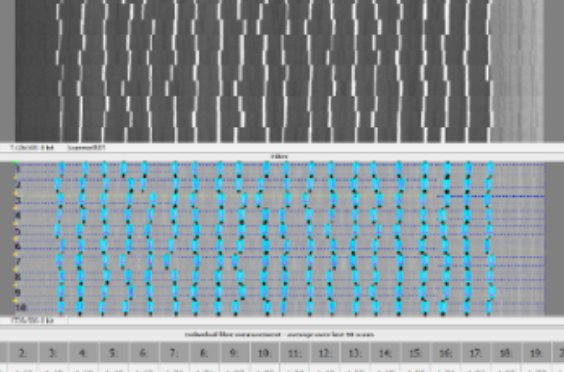

- Manufacturing